Greater Cincinnati Water Works (GCWW) visit

- Sep 30, 2025

- 4 min read

…. Quenching thirst of growing community

Date : July 12th 2025 ( 10 am – 12 .00 noon)

Address : 5651 Kellogg Ave, Cincinnati, OH 45230, USA

Report by : Ira Ramchandre

Guided by : Shital Ramchandre

I was very excited about this visit since I always wonder how water from nature reaches our faucet. My data always explains it whenever we wander into nature or visit some water dam in India but today was the best opportunity for me to deep dive. We reached the facility at 9.30 and waited in the meeting room for further instructions. Meanwhile we completed the waiver form. We were a total of 45 visitors so three groups were created and each group assigned with one guide. We were lucky because our guide was none other than one of the well-known TMM community member Mr. Niranjan Selar Uncle, and now we call him our Ninja Uncle. The other two groups are led by two other guides, Jeff and Max.

At 10.15 Jeff started to address all of us in the meeting room and he ran a few slides about GCWW history as well as overall plant illustration. Many of us asked questions and I was very curious to understand what it was all about. There are around 10 different stages in water filtration process and we were expected to visit and understand process from Step 5 -10 in this premises.

We understood from Jeff that on an average, GCWW treats about 132 million gallons of water a day and conducts about 600 tests daily throughout the water treatment and distribution process. Monitors and alarm systems are also located throughout the treatment plants and in the distribution system to continuously monitor water quality.

These tests include:

• Source water is tested routinely before it enters treatment plants

.• Treated Water is tested after each step in the treatment process.

• Water from the distribution system is sampled and analyzed regularly.

Most GCWW customers receive water from the Richard Miller Treatment Plant on the Ohio River (diagram below). Granular activated carbon (GAC) treatment at Miller gives GCWW an edge in water quality management. GAC allows us to use substantially less chlorine in the treatment process.

GCWW pioneered the use of GAC treatment and has one of the largest GAC facilities in the U.S.

After long discussion and question answers, “Ninja uncle” took us to various facilities in below order.

Facility 7 -> 6- > 5

Filtration: 6-million-gallon water passes through 47 Rapid Sand fillers per day.

Classification Basins : Secondary classification where water stabilizes for a few hours before it gets into Filtration.

Chemical house and hydraulic pump: Chemical gets added to incoming water with hydraulic jump techniques.

Facility: 8->9

CAG absorption

Ultraviolet treatment

Water samples from every stage are collected into the laboratory and go through automatic test process.

During this part I learnt very important substance which is called as “PFAS” PFAS (per- and polyfluoroalkyl substances) are a group of thousands of man-made chemicals used in many consumer and industrial products. PFAS compounds have been widely used in many household products like carpets, non-stick cookware and food wrappers. GCWW has taken additional planning steps to study and evaluate source water and treatment plant processes. These steps include:

Increased monitoring for PFAS compounds at both treatment plants

Identifying sources of potential contamination of the source waters. GCWW has obtained a grant to conduct monitoring and purchase new analytical equipment to better identify and track PFAS contamination sources. The best solution is to prevent compounds from entering the environment in the first place.

Facility 10 : Clearwalls

Clearwells are the buried reservoirs at the final step of the treatment process. Water gravity flows out of the clearwells to two pump stations almost 5 miles away.

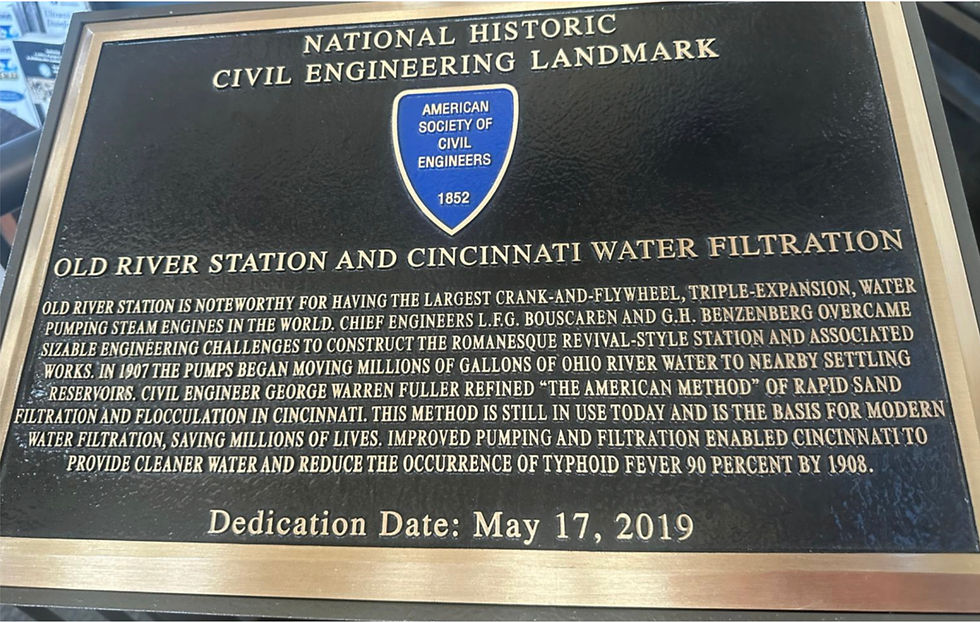

We also visited Old River station and the filtration process. This is the favorite spot for our Ninja uncle. He enjoys walking in this area of the plant after his lunch. There are over 500 acres on the plant property.

We concluded our visit around 12.30 noon. Jeff, Max and Ninja Uncle were very helpful during this visit. Thank you to all of you and TMM team.

I learnt some tips during this visit and while discussing with these experts. I am writing for everyone’s benefit:

Use only “cold” water for drinking and cooking

Replace the filter in accordance with manufacturer’s recommendations

Flush pipes before use. : water is often clogged by tiny air bubbles in the water. Flushing a small, steady stream of water from the highest tap location usually corrects this.

Drink water from a glass container. Some plastic or metal containers can add additional taste or odors to the water. Glass is least likely to impact the flavor.

Refrigerate water before drinking.

Unhook the garden hose.Even when not in use, odor compounds from the hose can seep back into the private plumbing system and cause an unpleasant odor and/or taste.

Clean the faucet aerators.

Clean the drains.

Contact a plumber to verify that correct plumbing connections exist.

Comments